Technical Ceramics

Technical Ceramics

ACM’s materials are processed from high grade ceramic powdcrs that may be custom formulated to meet application and customer requirements. These powders may be shaped or consolidated using several different processes.

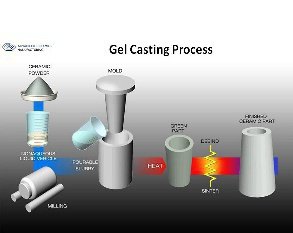

Non-Aqueous Gel Casting (NAGC)

Ceramic powders are suspended in a non-aqueous slurry with a good working viscosity. In general solids loadings readily achieve 50%-60% by volume. The non-aqueous slurry is cast and thermally gelled in a permanent or sacrificial mold.

Based on the quantity and complexity of the desired final components, molds can be economically fabricated from inexpensive materials, such as aluminum or wax. Green parts are processed through a thermal debinding step and a final high temperature sintering cycle to achieve consolidation.

Successful parts have been realized in sizes ranging from 0.100″ to 22″. ACM provides a range of ceramic materials already tailored to the gel-cast process; however, a development partner may provide a proprietary raw material which can be engineered into the gel-casting process. (Example powder systems: Zirconia, Silicon Nitride, Alumina, Alumina TiCN, SIALON, Aluminum Nitride, Boron Carbide, Silicon Carbide)

Hot Pressing

Because ceramic properties (and ultimately their performance) are highly dependent on the presence, size, and quantity of defects, it is often necessary to use advanced processing methods. Conventional firing operations “pressure-less sinter” ceramic powders to achieve dense bodies. The application of external pressure to powder bodies can enhance the consolidation process. This pressure enhanced consolidation is used

Standard Materials

ACM offers several standard ceramic materials available that may meet the needs of its customers.

Alumina (Al2O3) – Alumina is a versatile ceramic that is a work horse in the industry. If offers substantial wear and chemical stability. It is an excellent electrical insulator and low loss dielectric suitable for electro-magnetic applications.

Alumina Toughened Zirconia (ATZ) Grade: ATZ 1 HP – ATZ is ACM’s latest high strength ceramic material that offers extraordinary strength on par with the best state of the art materials. It combines that hardness of alumina with the strength and toughness of zirconia (“ceramic steel”).

Silicon Nitride (Si3N4) Grade: A34HP – Silicon nitride is a covalently bonded solid that offers a desirable combination of high strength, toughness, and hardness that are stable at high temperatures. In addition, it is very resistant to thermal shock. Combined with its low density, it is an attractive engineering material of interest for many applications (e.g. wear, engine, pump, cutting tool, biomedical, radomes).

Zirconia (ZrO2) Grade: 3YSZ – Zirconia’s offer the highest strength and toughness of all monolithic ceramics. Many zirconia’s structural advantages arise from its transformational toughening which lead to its nickname “ceramic steel.”

Other In addition to its standard materials, ACM also offers the ability to produce many other conventional and exotic/custom ceramic compounds. Such as: Silicon Carbide (SiC), SIALON, Aluminum Nitride (AlN), Zirconia (ZrO2), Zirconium Diboride (ZrB2), Titanium Diboride (TiB2), Titanium Nitride (TiN), Tantalum Carbide (TaC), Alumina TiCN, ZrB2-SiC Composites.

Specialty Ceramics • Mazon Gold: High Strength / High Electric Conductivity (EDM’able!) • Machinable: Alumina, Silicon Nitride • Fibrous Monoliths: Enhanced Damage Tolerance.

Custom Ceramic Fabrication

ACM will work with its customers to achieve the custom fabrication of their unqiue material and geometric needs. This may include custom formulation of ceramic materials and the development of customized manufacturing methods.

We frequently partner with both large and small business, universities, non-profits, and government agencies on specialized research programs.

Standard Geometries

ACM offers several standard ceramic materials available in plate and cylinder form. Standard geometries are often stocked and ready for immediate purchase.

In addition to its standard geometries, ACM also offers the ability to produce geometries to customer specifications.