Clavecore

ClaveCore combines many of the individual advantages of existing materials (solubility, layup rigidity, and pressurization) into a single material. It is a rigid tooling system that develops expanding pressure once it is thermally activated. Precision mandrels can be formed, laid up with conventional pre-preg materials, placed into a female cavity tool, and heated inside a conventional oven. Its pressurization behavior can be engineered via composition to control the pressure onset temperature and magnitude of pressure.

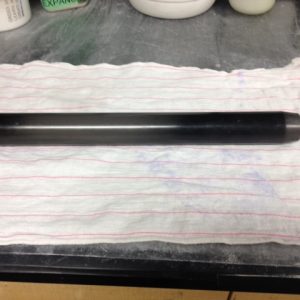

Mandrels are formed by filling a mold cavity with powder and heating the mold to 80-100°C. At this temperature, the powder reaches an activation point and the powder mixture is converted into a solid mandrel. The mold is allowed to cool to room temperature and the mandrel demolded.

When the mandrel material is used, it is wrapped with prepreg and placed inside a female mold. Upon thermal activation, the mandrel expands. It pushes and consolidates the individual plies against the containment tool surface.